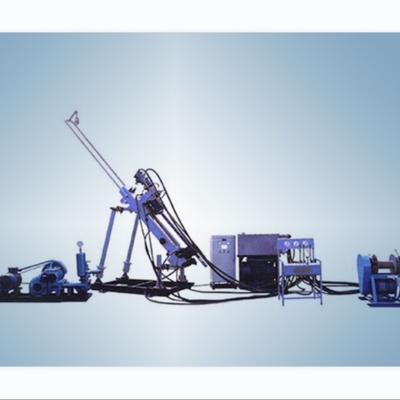

Top Hammer Surface Blasting Hole Drill Rig

Product Description

1-Technical Parameter

| Main Specifications |

T645 |

| Hole Range |

76-115 mm |

| Drill Pipe Dia. |

45/51mm |

| Drill Pipe Length |

3,660mm |

| Hole Depth.Max |

25M |

| Rock Drill |

ZY-105H |

| Percussion Power |

25 Kw |

| Rotation Torque |

1,180 Nm |

| Rotation rpm |

0-135 r/min |

| Drill pipe handling capacity |

6+1 Auto rod changer |

| Air Flow F.A.D. |

10 m³/ min |

| Air Working Pressure |

10 bar |

| Max Gradeability |

25° |

| Track Frame Oscillatiion Angle |

±10° |

| Tramming Speed Max |

3.6 km/h |

| Length |

12,000mm |

| Width |

2,550mm |

| Height |

3,200 |

| Weight |

14,500 kg |

Product Features

T640 and T645 drill rigs are respectively equipped witha 20kW and a 25kW high-frequency high-pressure full-hydraulic rock drillsthat are independently developed and manufactured by ourself. Besides.the folding booms and high-performance off-road design promote theefficiency in drilling small and medium-sized holes.

Safe & reliable

Cab: A spacious and comfortable safe cab which is ROps and FOPS approved, meets ergonomic requirements and delivers a scientific and comfortable driving experience, The seat with adiustable position is equipped with air-cushion shock absorption; Low noise and good visibility for drilling and collaring activities.

Guardrait: The drill rig top is equipped with guardrail and anti-slip stickers ensuring the safety of maintenance and service personnel; Meanwhile, the drill boom is also equipped with guardrails against drill rod fall-prevention.

Remote control: The product can be optionally equipped with a short-range remote control function, allowing operators to flexibly control drilling operations within a range of 100 meters, reducing risks during highwall mining or while getting on/off transportation vehicles.

High Productivity and flexible

Single engine:A single power unit simultaneously drives the operations of hydraulic system and screw ar end, improving the space utilization of the equipment while reducing energy consumption and maintenance costs

Long drill rod: drill rod configurations vary from3m, 4m, 5m, 6m, 7m, 9m and 10.7m, maximumly reducing the time of rod changing and enhancing the productivity.

Multi hole size: The heavy-duty reinforcement design within the functional range enables the equipment to simultaneously meet the rock driling applications under diferent working conditions and with different hole size.

Energy-saving and environment friendly

Dust collection capability: Based on diferent environmental conditions and customer needs, we provide such diferent solutions as dry dust collection, wet dust collection,and dry and wet mixed dust collection to meet the highest environmental reguirements.

Eficient air end: Excelent desien and manuiacturing technology of screw air end ensures drill rigs to obtain more energy-efficient high-pressure air power.

Controlsystem: The self-sensitive adiustment system meets the power requirements of drill rigs in various operating states at all times, while consuming the lowest energy during auxiliary operations of drill rigs.

Personalization

Remote control: Operators and equipment managers can easily access operational data of the equipment, making production scheduling and maintenance easier

Customization: We can provide customized designs for customers based on different working, conditions, environments, regulations and other special requirements.

Adaptability: Offer correspondingsolutions such as extreme cold climate kit, tropical desert kit, hieh altitude kit or hieh humidity kit for extreme working environments tomeet the needs of different regions around the world.

Company Profile

Glorytek Industry (Beijing)Co.,Ltd., located in Beijing, China, is an integrated corporation specialized in manufacturing and exporting top quality drilling equipment and drilling parts for decades. We are supported and assisted by a highly experienced team of designers and engineers that enable us to complete all the assigned projects successfully as per the specified requirement from our clients.

Our products are widely used in the scope of mining, water well drilling and exploration, anchor grouting project, side slope protection engineering, oil and gas engineering,underwater rock drilling & blasting operations of seaport channel, hydropower project, national defense projects ect.

FAQ

Q: Are you original manufacturer or trading company?

A: We are an integrated corporation specialized in manufacturing and exporting.

Q: Can you supply related drilling tools?

A: Yes, we can supply full set of drilling tools, such as drill pipe, tricone bit, PDC bit, drag bit, DTH hammer and bit. Moreover, we have drilling equipments like mud pump, air compressor, etc. as well.

Q: Which payment terms can you accept?

A: Normally we prefer 30% advance payment after purchase order by T/T, 70% remaining payment before shipping by T/T.

Q: How is your delivery time?

A: This will depend on your purchasing quantity. Normally we can deliver within 30days.

Q: How can you ensure the quality?

A: We have our professional QC and all the products will be strict inspection and testing for every order before shipping out.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!